Double Sided PCB Manufacturing

High-quality double-sided PCB prototyping and production tailored to your needs. Fast delivery, free DFM, and 15+ years of expertise. Start your project today!

Why Choose JHYPCB for Double Sided PCBs?

As a trusted PCB manufacturer in China, JHYPCB specializes in high-quality double-layer PCB solutions. With over 15 years of experience, we deliver boards tailored to your needs, from prototypes to mass production.

Double Sided PCB Definition

What is a Double Sided PCB?

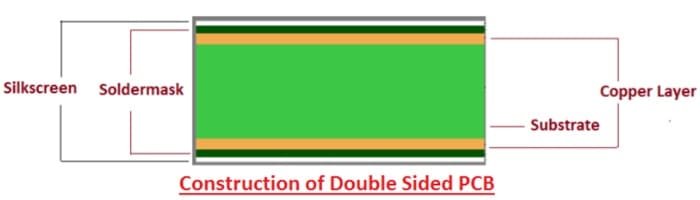

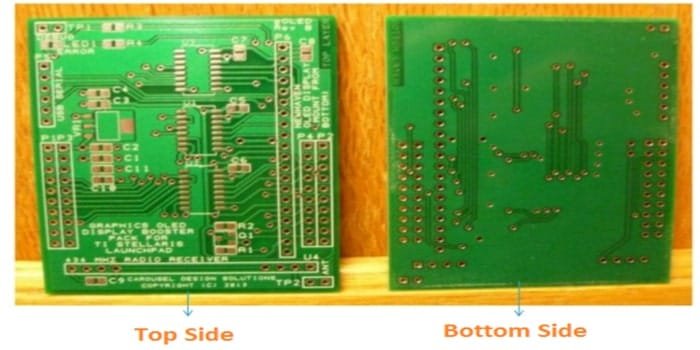

A double-sided PCB, also known as a double-layer PCB or 2-layer PCB, features conductive copper layers on both sides of a substrate, typically FR4. This design enables components and circuits on both top and bottom layers, connected via plated-through holes (vias) for enhanced functionality.

Key Features

- Higher Component Density: Supports compact designs for devices like mobile phones and IoT gadgets.

- Flexible Routing: Vias enable complex circuit connections, unlike single-sided PCBs.

- Wide Applications: Ideal for LED lighting, automotive dashboards, and RF systems.

At JHYPCB, we deliver high-quality double-sided PCB manufacturing. Get a free quote today!

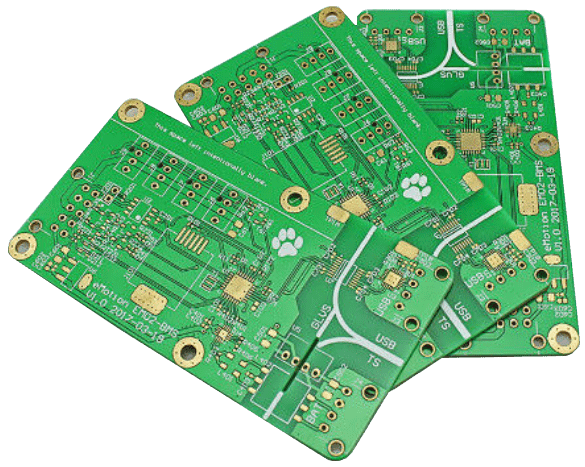

double sided circuit boards

Types of double-sided PCB

JHYPCB manufactures various double sided PCB types to suit diverse applications:

- Rigid PCB: FR4 substrate for consumer electronics like LED lighting.

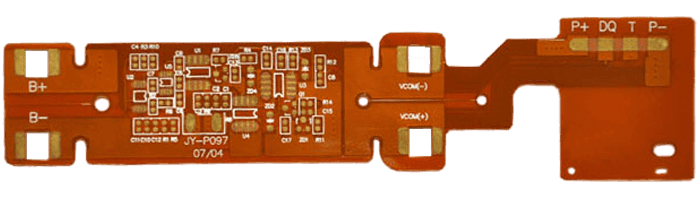

- Flexible PCB: Polyimide material for wearables.

- Metal Core PCB: Aluminum core for heat dissipation in high-power LEDs.

- High Tg PCB: Thermal stability for industrial controls.

- High Frequency PCB: Rogers material for RF and microwave circuits.

- Heavy Copper PCB: Thick copper for power electronics.

- Impedance Control PCB: Ensures signal integrity for high-speed circuits.

Need a custom double-layer PCB? Request a quote today!

Double Sided PCB Stack-Up

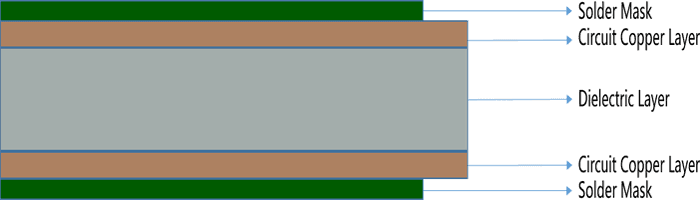

Understanding the stack-up is crucial for effective double sided PCB design. JHYPCB ensures precision in every layer:

Core Layers

- Top Conductive Layer: Copper for conductivity; gold/silver for plating.

- Dielectric/Base Layer: FR4, Polyimide, or PTFE as an insulator.

- Bottom Conductive Layer: Mirrors top layer for dual-sided circuits.

Protective Layers

- Surface Finish: OSP, Immersion Gold, or Tin to prevent oxidation.

- Solder Mask: Prevents solder bridges.

- Silkscreen: Labels components for assembly.

Optimize your design with JHYPCB’s expertise. Get started!

Construction of double-sided PCB

Double Sided PCB Layers

Double Sided PCB-Top Side and Button Side

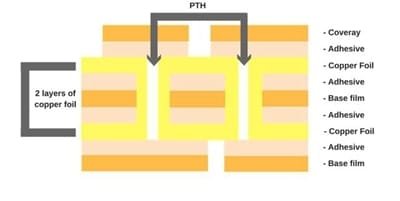

Double-sided Flexible PCB Circuit Board

Double-sided Flexible PCB Stack-up

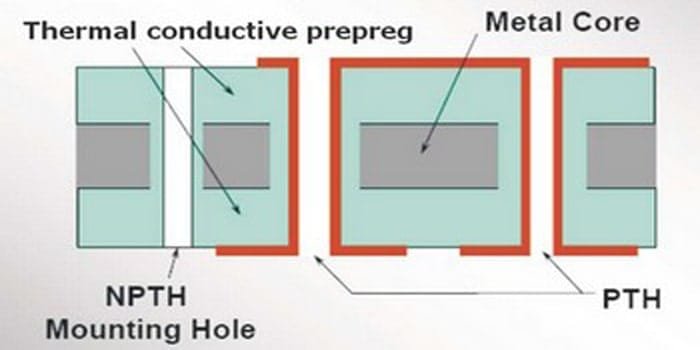

Structure of Double Sided MCPCB

Double Layer PCB Prototype Manufacturer

Benefits of Double Sided PCBs

Double sided PCBs offer significant advantages for modern electronics:

- Increased Component Density: Double the space for compact designs.

- Flexible Routing: Vias and dual layers reduce congestion.

- Better Signal Integrity: Ground plane minimizes noise.

- Space-Saving: Half the size of single-sided PCBs.

- Cost-Effective: Affordable alternative to multilayer PCBs.

Leverage these benefits with JHYPCB’s double layer PCB solutions. Request a quote now!

Double Sided PCB Prototyping

JHYPCB offers rapid double sided PCB prototype fabrication for applications like LED systems, wearables, and RF circuits.

Prototype Options

- Material Choices: FR4, metal-core, or flexible polyimide.

- Surface Finishes: Immersion Gold, OSP, Lead-Free Tin.

- Quick-Turn: 24-hour delivery for prototypes.

Start your double layer PCB project with us. Get a free quote today!

Double-Sided PCB Fabrication Capabilities

JHYPCB is a trusted double-sided PCB manufacturer in China, specializing in quick-turn prototyping and mass production. With over 15 years of experience, we deliver high-quality boards tailored to your needs. Explore our fabrication capabilities:

Key Fabrication Specifications

| Parameter | Details |

|---|---|

| Materials | FR4, Copper Core, Aluminum, Rogers (for high-frequency applications) |

| PCB Size | Up to 680mm x 1200mm |

| PCB Thickness | 0.2mm to 6.0mm (customizable) |

| Surface Finishes | OSP, Immersion Silver/Gold/Tin, Plated Gold, Flash Gold |

| Solder Mask | Green, Red, White, Black, Blue, Yellow |

Supported PCB Types

- Double-Sided FR4 PCB: Standard for consumer electronics.

- Double-Sided Copper-Clad PCB: High conductivity for power applications.

- Double-Sided Flexible PCB: Ideal for wearable devices.

- Double-Sided Rigid-Flex PCB: Combines flexibility and rigidity for complex designs.

- Double-Sided Rogers PCB: Perfect for RF and microwave circuits.

JHYPCB offers 24-hour quick-turn prototyping and free DFM analysis to ensure precision. Need a custom double-sided PCB? Request a quote today!

Double Sided PCB Assembly Process

Our double-sided PCB assembly uses advanced SMT and THT technologies for precision and reliability.

Assembly Steps

- Solder Paste Printing: Apply paste to both sides.

- Pick and Place: Place components accurately.

- Soldering: Reflow soldering for secure connections.

- Inspection: Ensure quality with visual and automated checks.

Need double-sided PCB assembly? Contact us for turnkey solutions!

Double Sided PCB Manufacturing Process

JHYPCB’s rigorous double sided PCB manufacturing process ensures quality and performance:

STEP 1

DFM Check

DFM Check

Verify design for manufacturability.

STEP 2

Drilling & PTH

Drilling & PTH

Create vias for layer connectivity.

STEP 3

Plating & Etching

Plating & Etching

Apply copper and remove excess.

STEP 4

Surface Finish & Testing

Surface Finish & Testing

Apply finishes and perform E-tests.

Applications of Double Sided PCBs

Double sided PCBs are versatile for industries including:

Consumer Electronics

Mobile phones, LED lighting

Power Applications

Inverters, UPS systems

Industrial Systems

HVAC, industrial controls

Automotive

Dashboards, sensors

Explore our solutions for your industry. Get a quote!

Frequently Asked Questions

What is the difference between single-sided and double-sided PCBs?

How long does it take to fabricate a double-sided PCB prototype?

What surface finishes are available?

Is there a minimum order quantity?

Recommended PCB Manufacturing Services

Related Posts

- Custom Circuit Board Printing

- Custom PCB Manufacturer In China

- Best PCB Manufacturer In China

- How To Search for a Reliable PCB Manufacturer

- PCB and PCBA Manufacturing Files

- Find Out Now, What Should You Do For Fast PCB Classification?

- What is a Multilayer PCB, and What Are the Advantages?

- Single-layer PCB vs. Double-sided PCB: How to Choose?

- How to Store PCB and PCBA?

- The Benefits Of Using Double Sided PCBs