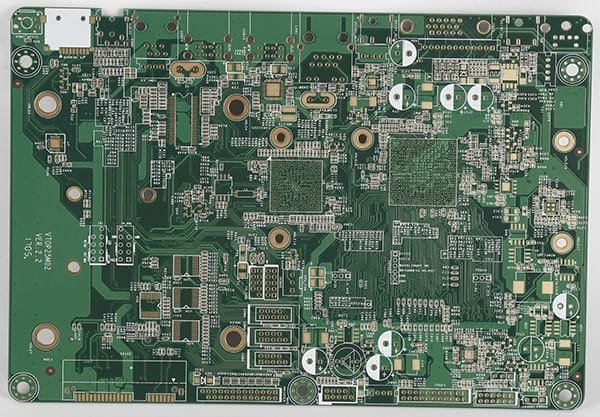

High-Quality PCB Prototypes, Fast and Affordable

Your Trusted Partner for PCB Prototyping

At JHYPCB, we deliver high-quality, cost-effective PCB prototype manufacturing with fast turnaround and exceptional customer service. From single-layer to multilayer, rigid to flexible PCBs, we make your electronic manufacturing process seamless.

Request Your Instant PCB Prototype Quote Now!

Why PCB Prototypes Matter

PCB prototypes are critical in the design and production process, serving as the initial versions of your printed circuit board to test functionality before mass production. They allow engineers and designers to:

Verify Design Feasibility

Ensure Functionality

Save Time and Costs

Improve Manufacturability

By choosing the right PCB prototype manufacturer, you ensure a high-quality, error-free final product. JHYPCB is your trusted partner for professional PCB prototyping services, offering advanced manufacturing and rigorous testing.

Key Parameters for Buying PCB Prototypes

Selecting the right specifications for your PCB prototype is essential for performance and quality. Here are the critical parameters to consider:

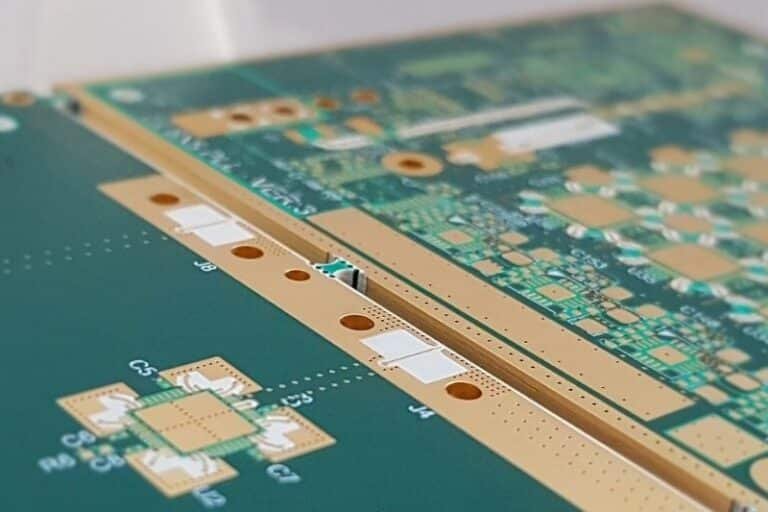

- Board Thickness: Measured in millimeters (0.4mm to 3.2mm), this affects the PCB’s strength and rigidity.

- Copper Thickness: Measured in ounces per square foot (oz/ft²) or microns (µm), it impacts conductivity and electrical performance.

- Number of Layers: From single-layer to multi-layer (4+ layers), this determines circuit complexity.

- Hole Size: Measured in millimeters or inches, hole size affects component placement and connectivity.

- Line Width: Measured in mils or millimeters, it influences current flow through copper traces.

- Surface Finish: Protects copper traces from oxidation and aids soldering. Popular options include HASL, ENIG, and OSP.

Choosing the right parameters ensures your PCB meets project requirements. Need help selecting? Contact our team at sales@pcbjhy.com.

How to Choose the Right PCB Prototype Supplier

Selecting a reliable PCB prototype supplier is key to project success. Here’s what to look for:

- Experience and Reputation: Compare suppliers based on expertise, customer reviews, and industry reputation.

- Specialization: Ensure the supplier can handle your specific PCB type (e.g., rigid, flexible, or rigid-flex).

- Turnaround Time: Opt for suppliers offering quick-turn services for faster prototyping.

- Quality Standards: Look for strict testing protocols, such as flying probe tests, to ensure reliability.

- Customer Support: Choose a supplier with responsive communication and 24/7 support.

At JHYPCB, we combine advanced equipment, experienced engineers, and rigorous quality control to deliver top-tier PCB prototypes. Learn more about our services.

Steps to Order PCB Prototypes

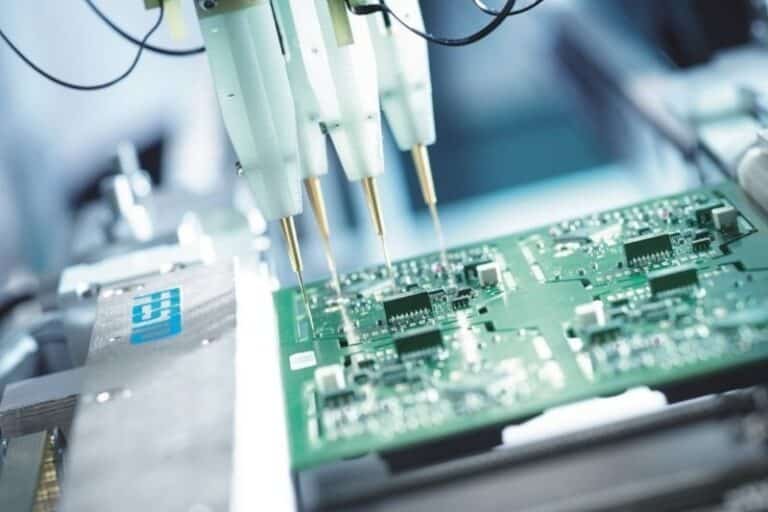

Ordering PCB prototypes with JHYPCB is simple and efficient. Follow these steps:

- Select Substrate Material: Choose materials like FR-4, CEM-1, aluminum, or copper based on your project needs.

- Submit Design Files: Send Gerber files (RX-274X), .brd, .pcb, or .pcbdoc files to our team.

- Receive a Quote: We’ll review your files and provide a detailed quote based on your specifications.

- Confirm the Order: Review the quote, make any adjustments, and confirm with payment.

- Manufacturing and Delivery: Our team manufactures your prototypes with precision and delivers them promptly.

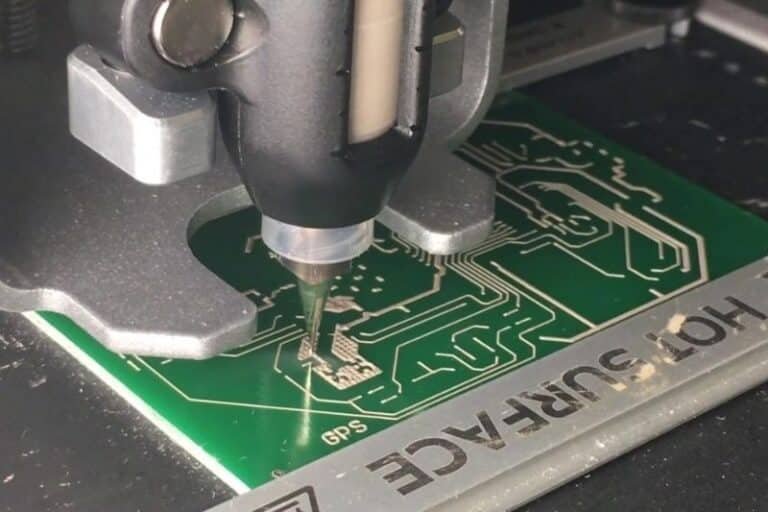

Inspecting Your PCB Prototypes

Upon receiving your PCB prototypes, thorough inspection ensures they meet your standards:

- Check for Physical Damage: Inspect packaging for signs of mishandling and report issues immediately.

- Verify Specifications: Confirm board thickness, copper thickness, layer count, hole size, line width, and surface finish.

- Perform Electrical Tests: Use a multimeter or oscilloscope to check for shorts, opens, or other electrical issues.

- Evaluate Visual Quality: Ensure solder mask, silkscreen, and overall finish meet your expectations.

JHYPCB’s prototypes undergo strict quality checks, including flying probe testing, to guarantee performance. Contact us for support with inspections.

Factors Affecting PCB Prototype Costs

The cost of PCB prototyping depends on several factors:

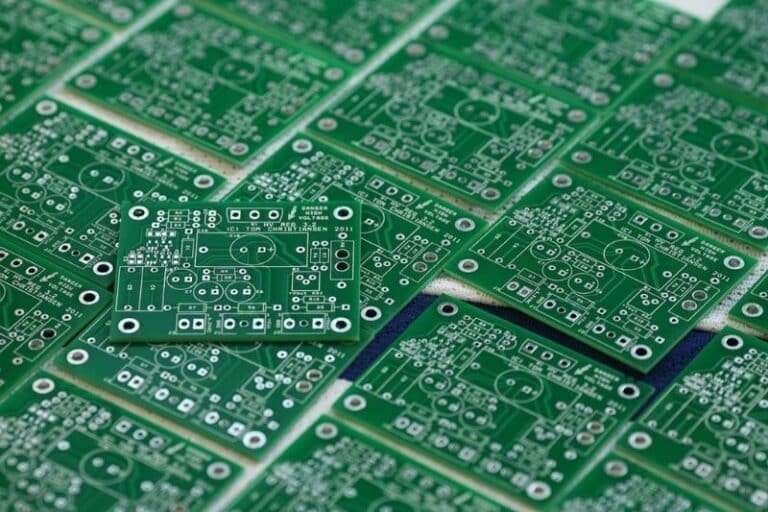

- Delivery Time: Faster turnaround increases costs but ensures quick delivery.

- Quantity: Small-batch orders are cost-effective for prototyping.

- Number of Layers: Multi-layer boards are more expensive than single-layer designs.

- Material Choice: Premium materials like aluminum or copper increase costs.

- Manufacturing Process: Complex processes like impedance control add to expenses.

- Engineering and Transport Costs: Factor in design reviews and shipping fees.

At JHYPCB, we offer competitive pricing without compromising quality. Request an instant quote to see how we can meet your budget.

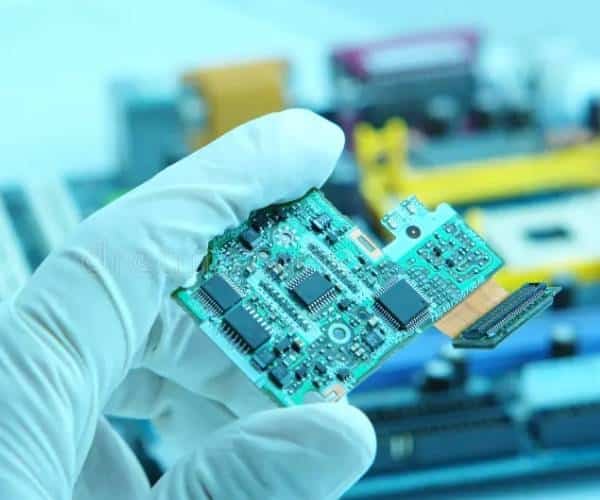

Why Choose JHYPCB for PCB Prototyping?

High Quality

Advanced equipment and strict testing ensure reliable prototypes.

Competitive Pricing

Affordable solutions for small-batch and quick-turn needs.

Exceptional Service

24/7 customer support from our dedicated team.

Fast Turnaround

Super-fast manufacturing to keep your project on schedule.

FAQ

Most frequent questions and answers

PCB prototype manufacturing needs to provide PCB or Gerber files, board making instructions: PCB layer number, board thickness, surface treatment, silkscreen legend color, IPC standard, panelization requirements, material, pad process, solder mask color, whether there is impedance requirement, etc. . The Gerber file formats acceptable to our company are Gerber RX-274X, .brd, .pcb, .pcbdoc, etc.

There are many things to pay attention to when ordering PCB prototype manufacturing, and the price is one of the focuses of buyers’ attention. Factors affecting the cost of PCB prototype manufacturing include:

1) Delivery Cycle

2) Quantity

3) Number of PCB Layers

4) Manufacturing Process

5) PCB Material

6) Engineering Cost

7) Location of the PCB Supplier

8) Transportation Cost

For more detailed instructions, please refer to here.

Advanced Learning:

We all know the importance of PCB prototyping before mass production because PCB prototyping can provide us with the following benefits:

- Check the possible errors in the PCB design process;

- Functional test;

- Save time and cost;

- Manufacturability inspection;

- Can help us improve our design;

- Ensure that the final product is error-free;

- Ensure successful mass production

You can click here and read the following article for more information: