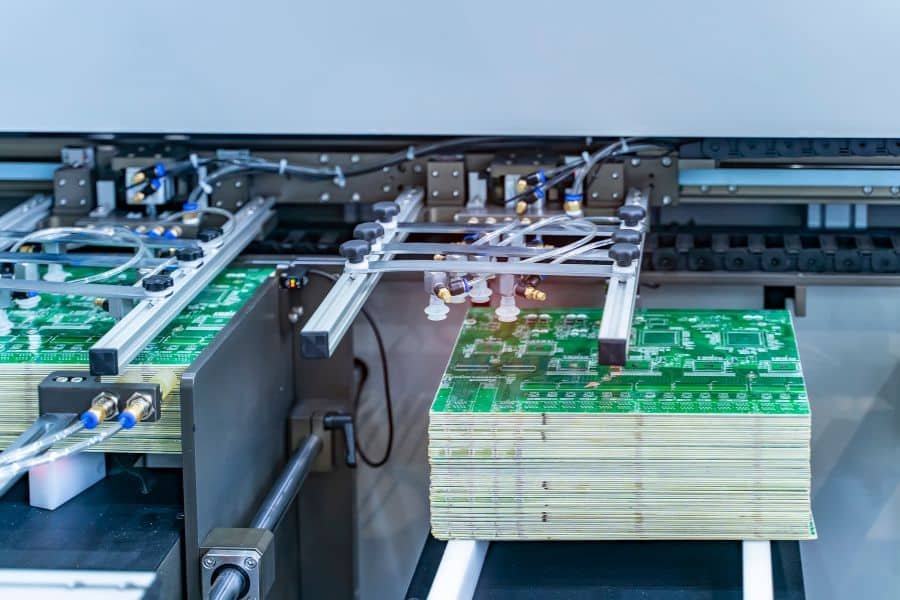

3 Special Reminders for Printed Circuit Board Assembly (PCBA)

When it comes to printed circuit board assembly (PCBA), overlooking even the smallest details can lead to costly delays and quality issues. Discover three critical reminders – parts overages, panelization, and break-away rails – that will streamline your PCBA project and ensure flawless results from a leading China PCB manufacturer.

3 Special Reminders for Printed Circuit Board Assembly (PCBA) Read More »