Navigating The PCB Manufacturing Process Part 4: Solder Mask, Silkscreen, Surface Finish

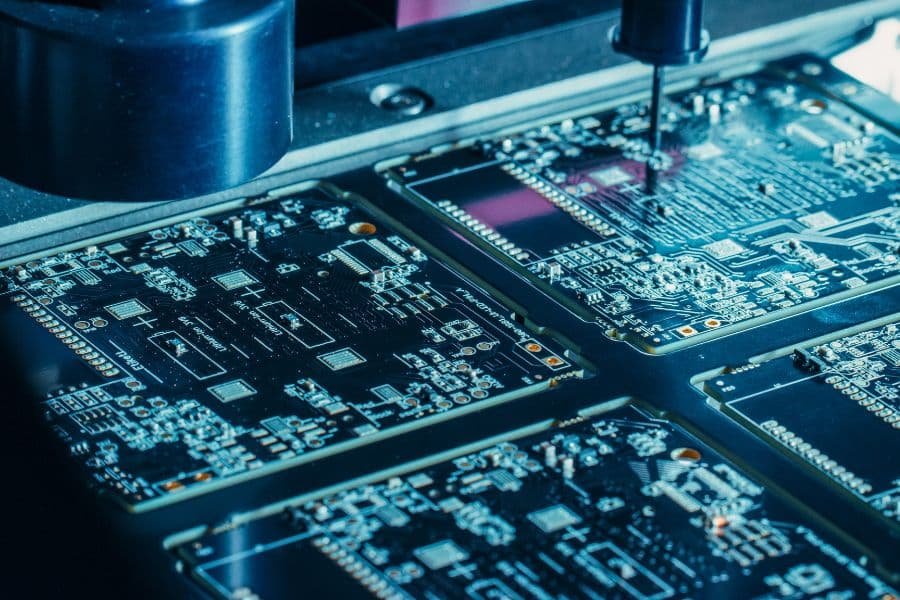

We have now covered initial PCB production processes – substrate preparation, imaging, plating, etching to form circuitry. The board is now a semi-finished product. This section explains solder mask application to shield copper traces, silkscreen printing for informational markings and labels, and surface metal treatments to protect pads from oxidation while promoting soldering. With these enhancements, boards are fully ready for electronics assembly.

Navigating The PCB Manufacturing Process Part 4: Solder Mask, Silkscreen, Surface Finish Read More »