Introduction

In today’s fast-paced electronics industry, efficiency and quality are paramount. Whether you’re a startup developing a groundbreaking device or an established company launching a new product line, the journey from concept to finished circuit board can be complex. This is where turnkey PCB manufacturing and assembly comes into play, offering a streamlined solution that’s revolutionizing the way electronics are produced.

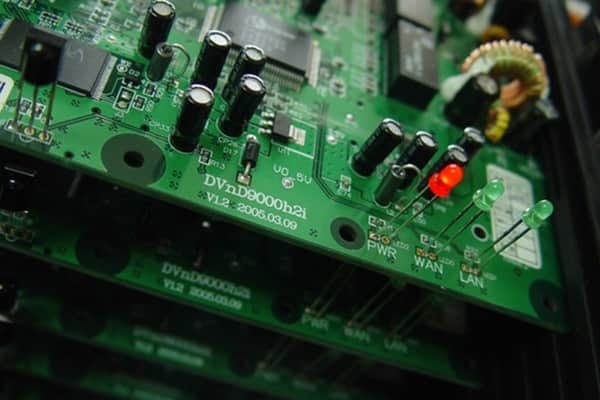

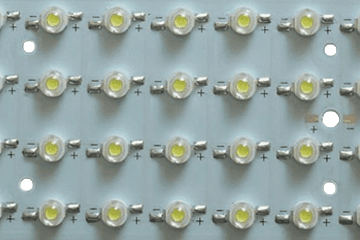

Printed Circuit Boards (PCBs) are the unsung heroes of modern electronics, serving as the foundation for everything from smartphones to advanced medical devices. Traditionally, the process of bringing a PCB to life involved multiple steps and often multiple vendors – design, fabrication, component sourcing, and assembly. Each transition between these stages introduced potential for delays, miscommunications, and quality issues.

Enter turnkey PCB manufacturing and assembly – a comprehensive approach that combines all these crucial steps under one roof. This integrated service model is gaining traction among electronics manufacturers worldwide, and for good reason. By entrusting your entire PCB production process to a single, specialized facility, you can unlock a host of benefits that go beyond mere convenience.

In this article, we’ll explore the advantages of choosing a turnkey PCB assembly manufacturer, particularly those based in China, known for their cost-effective yet high-quality services. We’ll delve into how this approach can save you time and money, enhance quality control, and simplify project management. Whether you’re looking for PCB assembly services for a small prototype run or large-scale production, understanding the turnkey model could be the key to streamlining your manufacturing process and gaining a competitive edge.

Join us as we unpack the world of turnkey PCB manufacturing and assembly, and discover why more and more companies are turning to this efficient, all-in-one solution for their electronics production needs.

The Rise of Turnkey PCB Assembly Services

In recent years, the electronics manufacturing landscape has witnessed a significant shift towards integrated solutions. At the forefront of this trend is the growing popularity of turnkey PCB assembly services. But what’s driving this change, and why are companies increasingly drawn to this all-in-one approach?

Growing Demand for Integrated Solutions

The modern electronics market moves at breakneck speed. Product lifecycles are shorter than ever, and the pressure to innovate is relentless. In this fast-paced environment, companies are constantly looking for ways to streamline their operations and bring products to market faster. Turnkey PCB assembly services have emerged as a powerful solution to these challenges.

By offering a complete package – from PCB fabrication to final assembly – turnkey providers are meeting the industry’s demand for speed, efficiency, and simplicity. This integrated approach eliminates the need for companies to juggle multiple vendors, reducing complexity and potential points of failure in the production process.

Why Companies are Choosing Turnkey Options

The appeal of turnkey PCB assembly extends beyond mere convenience. Here are some key reasons why businesses, from startups to multinational corporations, are gravitating towards this model:

- Time Efficiency: In the electronics industry, time is often the most critical resource. Turnkey services significantly reduce lead times by eliminating the delays associated with transferring projects between different vendors.

- Cost Savings: While the upfront cost might sometimes be higher, turnkey solutions often prove more economical in the long run. They eliminate hidden costs associated with managing multiple suppliers and reduce the risk of costly errors.

- Quality Assurance: With a single entity overseeing the entire process, there’s greater consistency in quality control. This integrated approach allows for better tracking and faster resolution of any issues that may arise.

- Simplified Project Management: Managing a single turnkey provider is far simpler than coordinating with multiple vendors. This streamlined communication often leads to smoother project execution and fewer misunderstandings.

- Access to Expertise: Top turnkey PCB assembly manufacturers, particularly those in hubs like China, often have extensive experience across various industries. This broad expertise can be invaluable, especially for companies entering new markets or working with cutting-edge technologies.

- Flexibility and Scalability: Whether you need a small batch for prototyping or a large run for mass production, turnkey providers can usually accommodate varying scales of production more easily than traditional fragmented supply chains.

As the electronics industry continues to evolve, the demand for turnkey PCB assembly services is likely to grow even further. Companies are recognizing that in a world where agility and efficiency are key to success, the integrated approach offered by turnkey solutions is not just a convenience – it’s a competitive advantage.

Key Benefits of Turnkey PCB Manufacturing and Assembly

Now that we understand why turnkey PCB assembly services are gaining popularity, let’s dive deeper into the specific benefits this approach offers. Whether you’re a startup looking for efficient prototyping or an established company seeking to optimize your production process, these advantages can make a significant impact on your bottom line and product quality.

1. Cost Efficiency

One of the most compelling reasons to choose a turnkey PCB assembly manufacturer is the potential for substantial cost savings:

- Reduced Transportation and Handling Costs: With all processes happening under one roof, you eliminate the need for shipping partially completed products between different vendors. This not only saves on shipping costs but also reduces the risk of damage during transit.

- Economies of Scale in Component Procurement: Turnkey providers, especially those operating as PCB assembly factories in China, often have established relationships with component suppliers. They can leverage their bulk purchasing power to secure better prices on components, passing these savings on to you.

- Streamlined Operations: By consolidating multiple steps, turnkey solutions eliminate redundancies and optimize the overall production process, leading to lower operational costs.

2. Time Savings

In the fast-paced world of electronics manufacturing, time is often as valuable as money. Turnkey PCB assembly services can significantly reduce your time-to-market:

- Streamlined Production Process: With design, fabrication, and assembly all happening in one place, there’s no time lost in transferring projects between different facilities.

- Faster Turnaround Times: Turnkey providers can often offer quicker turnaround times than traditional fragmented processes, especially for prototype PCB assembly or small batch productions.

- Reduced Setup Time: Once your project is set up with a turnkey provider, subsequent orders can be processed much more quickly, as all the necessary information and components are already in place.

3. Enhanced Quality Control

Quality is paramount in PCB manufacturing, and turnkey solutions offer several advantages in this regard:

- Consistent Standards Throughout the Process: With a single entity overseeing the entire production, there’s greater consistency in quality standards from design to final assembly.

- Reduced Risk of Errors and Defects: The integrated nature of turnkey services minimizes the risk of miscommunication or misinterpretation that can occur when multiple vendors are involved.

- Comprehensive Testing: Many turnkey PCB assembly services include thorough testing at various stages of production, ensuring that any issues are caught and resolved early.

4. Simplified Project Management

Managing a complex PCB production process becomes much easier with a turnkey approach:

- Single Point of Contact: Instead of coordinating with multiple vendors, you have one point of contact for all aspects of your project, from initial design to final delivery.

- Easier Communication and Coordination: With all teams working under the same roof, information flows more smoothly, reducing the risk of miscommunication and delays.

- Streamlined Problem-Solving: If issues arise, they can be addressed more quickly and efficiently within an integrated system.

5. Access to Specialized Expertise

Top turnkey PCB assembly manufacturers, particularly those offering PCB assembly services in China, often have extensive experience across various industries:

- Broad Knowledge Base: These providers work with a diverse range of clients, giving them insights into best practices across different sectors.

- Up-to-Date Technology: Leading turnkey providers invest in the latest equipment and techniques, ensuring your project benefits from cutting-edge technology.

- Design for Manufacturability (DFM) Support: Many turnkey services offer DFM advice, helping you optimize your designs for efficient production.

By choosing a turnkey PCB assembly service, you’re not just simplifying your supply chain – you’re tapping into a wealth of expertise and efficiency that can give your products a competitive edge. In the next section, we’ll discuss how to choose the right PCB assembly manufacturer for your specific needs.

Choosing the Right PCB Assembly Manufacturer

Now that we’ve explored the benefits of turnkey PCB manufacturing and assembly, let’s focus on how to select the right partner for your needs. Choosing the appropriate PCB assembly manufacturer can make all the difference in the success of your project. Here are key factors to consider and questions to ask when evaluating potential turnkey providers.

Factors to Consider When Selecting a Turnkey Provider

- Experience and Expertise

- How long has the company been in business?

- Do they have experience with projects similar to yours?

- Are they familiar with your industry’s specific requirements?

Look for a PCB assembly manufacturer with a proven track record in your industry. Their experience can provide valuable insights and help avoid common pitfalls.

- Technical Capabilities

- What types of PCB can they manufacture? (e.g., rigid, flex, rigid-flex)

- What surface finish options do they offer?

- Can they handle complex designs or high-density boards?

Ensure the manufacturer’s capabilities align with your current and future needs. A versatile provider can accommodate your project as it evolves.

- Quality Control Processes

- What quality certifications do they hold? (e.g., ISO 9001, IPC standards)

- What inspection and testing procedures do they use?

- How do they handle defects or quality issues?

Quality should be a top priority. Look for manufacturers with robust quality management systems and a commitment to continuous improvement.

- Turnaround Time and Flexibility

- What are their standard lead times for prototypes and production runs?

- Can they accommodate rush orders when needed?

- How do they handle design changes or revisions?

A responsive manufacturer can help you meet tight deadlines and adapt to changing market demands.

- Communication and Customer Service

- How easy is it to reach their technical support team?

- Do they offer online tracking of your order status?

- Are they willing to provide regular updates throughout the production process?

Clear, open communication is crucial for a smooth manufacturing process. Look for a provider that values transparency and responsiveness.

- Pricing and Cost Structure

- How competitive are their prices?

- Do they offer volume discounts?

- Are there any hidden fees or charges?

While cost shouldn’t be the only factor, understanding the pricing structure helps you budget effectively and avoid surprises.

- Location and Logistics

- Where are their manufacturing facilities located?

- What shipping options do they offer?

- How do they handle customs and international shipping?

Consider the pros and cons of domestic versus international manufacturers. While PCB assembly in China often offers cost advantages, factors like shipping time and import regulations should also be considered.

The Importance of Experience and Capabilities

When it comes to PCB assembly services, experience matters. A seasoned turnkey provider brings more than just manufacturing capacity to the table:

- Industry Knowledge: Experienced manufacturers understand the nuances of different industries, from consumer electronics to aerospace.

- Problem-Solving Skills: They’ve likely encountered and solved a wide range of challenges, which can be invaluable when issues arise.

- Design for Manufacturability (DFM) Expertise: Seasoned providers can offer insights to improve your design for more efficient production.

- Supply Chain Relationships: Established manufacturers often have strong relationships with component suppliers, potentially leading to better pricing and availability.

Making Your Decision

After considering these factors, don’t hesitate to ask for samples or references. Many reputable PCB assembly manufacturers are happy to provide examples of their work or put you in touch with satisfied customers.

Remember, the cheapest option isn’t always the best. Look for a balance of quality, capability, communication, and cost. A reliable turnkey PCB assembly partner can become a valuable asset to your business, contributing to your product’s quality and your company’s success.

PCB Assembly in China: A Global Hub

When it comes to PCB assembly, China has emerged as a dominant force in the global market. Many companies, from startups to multinational corporations, are turning to Chinese manufacturers for their PCB assembly needs. But what makes China such an attractive option, and how do Chinese manufacturers maintain quality while offering competitive prices? Let’s delve into the advantages of choosing a PCB assembly factory in China and explore how they’ve become a cornerstone of the global electronics industry.

Advantages of Choosing a PCB Assembly Factory in China

- Cost-Effectiveness China’s PCB assembly industry offers a compelling cost advantage, making it an attractive option for businesses of all sizes. This cost-effectiveness stems from several factors:

- Lower labor costs compared to many Western countries

- Economies of scale due to the high volume of production

- Well-established supply chains that reduce material costs

- Government incentives and support for the electronics manufacturing industry

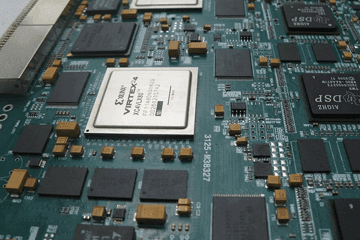

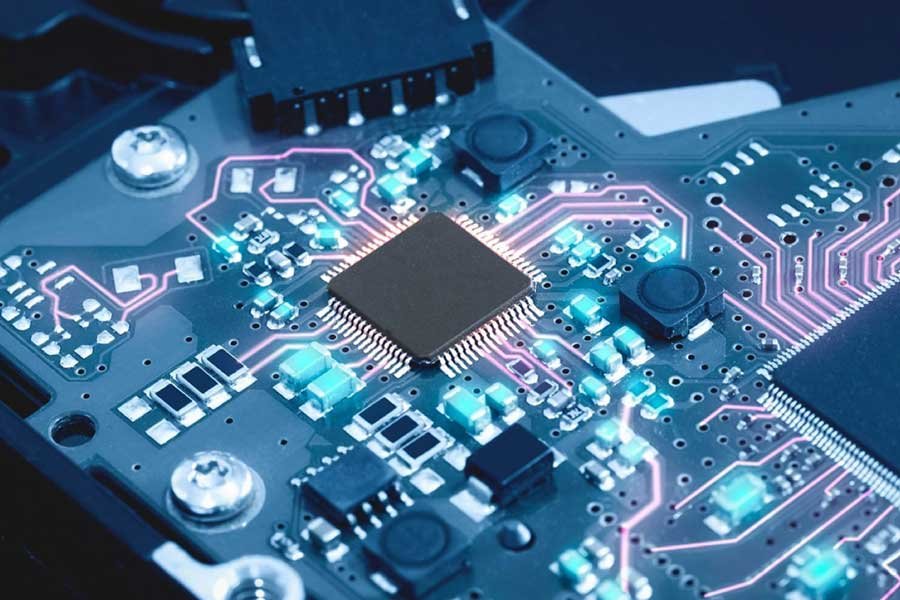

- Advanced Technology and Equipment Contrary to outdated perceptions, many Chinese PCB assembly factories are equipped with state-of-the-art technology:

- Advanced SMT (Surface Mount Technology) lines

- Automated optical inspection (AOI) systems

- X-ray inspection capabilities

- Advanced testing equipment for ensuring product quality and reliability

- Expertise and Experience China’s long history in electronics manufacturing has resulted in a deep pool of expertise:

- Skilled engineers and technicians with extensive experience in PCB assembly

- Familiarity with a wide range of industries and applications

- Ability to handle complex designs and high-density boards

- Quick Turnaround Times Chinese manufacturers are known for their ability to deliver products quickly:

- Efficient production processes honed over years of experience

- 24/7 production capabilities in many facilities

- Streamlined supply chains that reduce delays in component sourcing

- Flexibility and Scalability Whether you need a small batch for prototyping or a large run for mass production, Chinese PCB assembly services can accommodate:

- Ability to handle both low-volume, high-mix and high-volume, low-mix production

- Scalable production capacity to meet growing demand

- Flexibility to adapt to changing requirements or designs

How Chinese Manufacturers Maintain Quality While Offering Competitive Prices

- Stringent Quality Control Measures Top PCB assembly manufacturers in China implement robust quality management systems:

- ISO 9001 certification for quality management

- IPC standards compliance for electronics manufacturing

- Multiple inspection stages throughout the production process

- Use of advanced testing equipment for thorough quality assurance

- Continuous Investment in Technology To stay competitive, Chinese manufacturers regularly upgrade their equipment and processes:

- Adoption of Industry 4.0 principles for smart manufacturing

- Implementation of automation to improve precision and reduce human error

- Ongoing staff training to keep up with technological advancements

- Strong Supply Chain Management Efficient supply chain management helps maintain quality while keeping costs down:

- Close relationships with component suppliers ensure authentic, high-quality parts

- Just-in-time inventory systems reduce storage costs without compromising on quality

- Rigorous supplier vetting processes to maintain a reliable supply chain

- Focus on Value-Added Services Many Chinese PCB assembly factories go beyond basic manufacturing to offer comprehensive solutions:

- Design for Manufacturing (DFM) assistance to optimize designs for production

- Component sourcing services to ensure the best quality-to-price ratio

- Comprehensive testing services, including functional and environmental testing

- Regulatory Compliance Reputable Chinese manufacturers ensure compliance with international standards and regulations:

- RoHS and REACH compliance for environmental safety

- UL certification for product safety

- Compliance with industry-specific standards (e.g., medical, automotive, aerospace)

By leveraging these advantages and maintaining a strong focus on quality, Chinese PCB assembly manufacturers have positioned themselves as leaders in the global market. They offer a compelling combination of cost-effectiveness, technical capability, and reliability that makes them an attractive choice for companies worldwide.

However, it’s important to note that not all Chinese manufacturers are equal. When choosing a PCB assembly partner in China, it’s crucial to do your due diligence, ask for certifications and references, and if possible, visit the facility in person or via virtual tour. By selecting a reputable and experienced Chinese manufacturer, you can benefit from high-quality PCB assembly services at competitive prices, giving your products a significant edge in the market.

Comparison: Turnkey PCB Assembly vs. Traditional Separated Processes

To truly understand the value of turnkey PCB assembly services, it’s helpful to compare this integrated approach with the traditional separated processes. Let’s break down the key differences in terms of cost, time efficiency, and quality outcomes.

Cost Analysis

- Turnkey PCB Assembly

- Initial Costs: May appear higher due to the comprehensive service package.

- Hidden Costs: Minimal, as most aspects are included in the quoted price.

- Long-term Savings: Significant, due to streamlined processes and economies of scale.

- Volume Discounts: Often available, with better rates for larger orders.

- Traditional Separated Processes

- Initial Costs: May seem lower when looking at individual stages.

- Hidden Costs: Can be substantial, including shipping between vendors, project management, and potential rework.

- Long-term Expenses: Higher due to inefficiencies and potential miscommunications.

- Volume Discounts: May be available from individual vendors, but less comprehensive.

Key Takeaway: While turnkey services might appear more expensive initially, they often result in significant cost savings over time, especially for medium to large-scale productions.

Time Efficiency

- Turnkey PCB Assembly

- Lead Times: Generally shorter, as all processes are coordinated under one roof.

- Design to Production: Faster transition, with DFM (Design for Manufacturing) feedback integrated early.

- Revisions and Changes: Quicker implementation of changes across the entire process.

- Scaling Production: Seamless scaling from prototypes to full production runs.

- Traditional Separated Processes

- Lead Times: Often longer due to transitions between different vendors.

- Design to Production: Can be delayed by back-and-forth between design and manufacturing teams.

- Revisions and Changes: May require coordination with multiple vendors, leading to delays.

- Scaling Production: May involve finding new vendors or renegotiating with existing ones.

Key Takeaway: Turnkey PCB assembly services significantly reduce time-to-market, which can be crucial in fast-paced industries.

Quality Outcomes

- Turnkey PCB Assembly

- Consistency: High, due to unified quality control standards across all stages.

- Error Detection: Early and efficient, with issues caught and resolved quickly.

- Accountability: Clear, with a single point of responsibility for the entire process.

- Optimization: Continuous, with insights from manufacturing fed back into design.

- Traditional Separated Processes

- Consistency: Can vary between different stages and vendors.

- Error Detection: May be delayed, with issues sometimes only discovered late in the process.

- Accountability: Can be complex, with multiple vendors potentially shifting responsibility.

- Optimization: Often requires more effort to implement improvements across different vendors.

Key Takeaway: Turnkey PCB assembly typically results in higher overall quality and consistency, with faster resolution of any issues that do arise.

Real-World Scenario: Prototype to Production

Let’s consider a hypothetical scenario where a company needs to produce a new IoT device, starting with prototypes and moving to full production.

Turnkey PCB Assembly Approach:

- The company submits their design to a turnkey PCB assembly manufacturer in China.

- The manufacturer provides DFM feedback, optimizing the design for production.

- Prototypes are quickly produced and tested.

- After approval, full production begins without delay, using the same optimized processes.

- The entire process, from design submission to the start of full production, takes 4-6 weeks.

Traditional Separated Processes:

- The company sends the design to a PCB fabrication house.

- Bare PCBs are produced and shipped to the company.

- The company sources components from various suppliers.

- The PCBs and components are sent to an assembly house.

- Prototypes are produced and sent back to the company for testing.

- Any design changes require repeating steps 1-5.

- For full production, the company may need to find new vendors capable of higher volumes.

- The entire process can take 8-12 weeks or more, with higher risks of delays and miscommunications.

This comparison illustrates why many companies, especially those looking for efficient PCB assembly services or seeking a reliable PCB assembly manufacturer, are turning to turnkey solutions. The integrated approach offers a smoother, faster, and often more cost-effective path from design to final product.

Case Study: Successful Implementation of Turnkey PCB Assembly

To illustrate the real-world benefits of turnkey PCB assembly, let’s examine the case of TechInnovate, a growing tech startup that successfully transitioned to a turnkey PCB assembly solution.

Company Background

TechInnovate is a startup developing smart home devices. They were initially using traditional separated processes for their PCB manufacturing and assembly needs, but as demand for their products grew, they faced challenges with scaling production, maintaining quality, and meeting market demands.

The Challenge

- Inconsistent quality across different batches

- Long lead times, often 10-12 weeks from design to finished product

- Difficulty in managing multiple vendors across different countries

- Rising costs due to shipping between vendors and occasional rework

The Solution

After careful consideration, TechInnovate partnered with a reputable turnkey PCB assembly manufacturer in China. The chosen partner offered:

- Comprehensive DFM (Design for Manufacturing) review

- Advanced SMT capabilities for high-density boards

- Rigorous quality control processes

- Flexible production capacity to accommodate growth

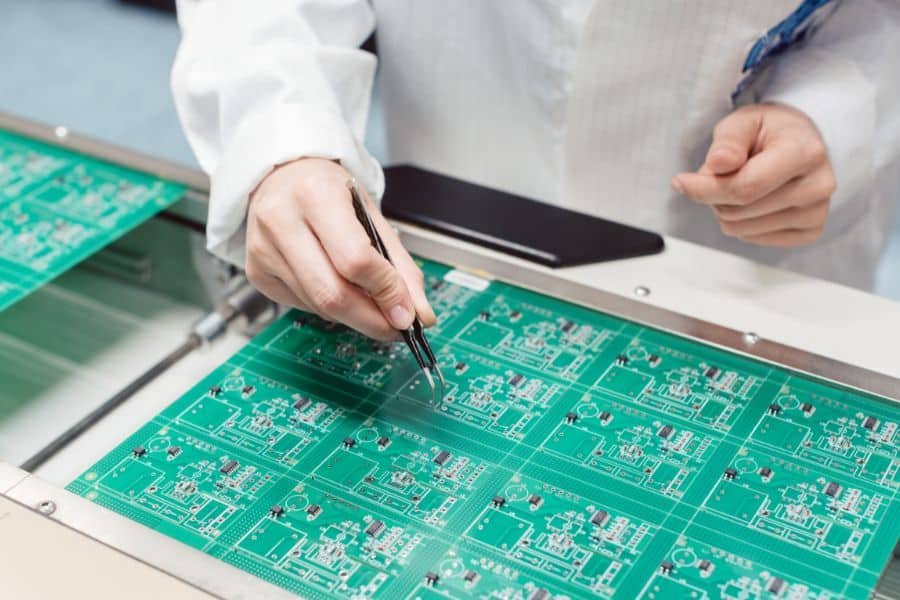

The Implementation Process

- Design Optimization: The turnkey provider reviewed TechInnovate’s designs and suggested improvements for manufacturability, reducing potential issues.

- Prototyping: Rapid prototyping was completed within 2 weeks, allowing for quick design iterations.

- Component Sourcing: The provider leveraged its supply chain relationships to source high-quality components at competitive prices.

- Production Scaling: As demand grew, the provider seamlessly scaled up production without compromising on quality or lead times.

The Results

After six months of implementing the turnkey PCB assembly solution, TechInnovate saw significant improvements:

- Lead Time Reduction: Average time from design to finished product decreased from 10-12 weeks to 4-5 weeks.

- Cost Savings: Overall production costs reduced by 23% due to improved efficiency and economies of scale.

- Quality Improvement: Defect rate decreased from 3.5% to less than 0.5%.

- Scalability: Production capacity increased by 300% without requiring additional resource management from TechInnovate.

- Time-to-Market: Faster production cycles allowed TechInnovate to respond more quickly to market demands, launching new product variations 40% faster than before.

Key Takeaways

TechInnovate’s success story highlights several key advantages of turnkey PCB assembly:

- Streamlined process from design to production

- Significant time and cost savings

- Improved product quality and consistency

- Enhanced ability to scale production

- Faster time-to-market for new products

This case study demonstrates how partnering with the right turnkey PCB assembly manufacturer can transform a company’s production capabilities, enabling growth and improving competitiveness in the market.

The Future of PCB Manufacturing and Assembly

As we look ahead, the PCB manufacturing and assembly industry is poised for exciting developments. These advancements will further enhance the benefits of turnkey PCB assembly services. Let’s explore some of the emerging trends shaping the future of this critical industry.

1. Industry 4.0 and Smart Manufacturing

- IoT Integration: PCB assembly factories are increasingly incorporating IoT devices for real-time monitoring and data collection.

- AI and Machine Learning: These technologies are being used to optimize production processes, predict maintenance needs, and improve quality control.

- Digital Twins: Virtual replicas of physical PCB assembly lines allow for better planning and optimization.

2. Advanced Materials and Designs

- Flexible and Stretchable PCBs: As devices become more wearable and integrated into various products, demand for flexible PCBs is rising.

- High-Frequency Materials: With the growth of 5G and beyond, PCBs designed for high-frequency applications are becoming more common.

- Miniaturization: Continued push for smaller, more densely packed PCBs to meet the demands of compact electronic devices.

3. Sustainability and Green Manufacturing

- Eco-Friendly Materials: Increased use of biodegradable and recyclable materials in PCB manufacturing.

- Energy Efficiency: Implementation of more energy-efficient processes and equipment in PCB assembly factories.

- Waste Reduction: Advanced manufacturing techniques to minimize waste and improve material utilization.

4. Additive Manufacturing in PCB Production

- 3D Printed Electronics: Potential for printing entire PCBs, including conductive traces and components.

- Rapid Prototyping: 3D printing technologies enabling even faster prototyping of PCB designs.

- Customization: Ability to easily produce small batches of highly customized PCBs.

5. Enhanced Automation and Robotics

- Collaborative Robots: Integration of cobots in PCB assembly lines for improved efficiency and flexibility.

- Automated Optical Inspection (AOI): More advanced AOI systems using AI for even more accurate defect detection.

- Automated Component Placement: Further improvements in accuracy and speed of component placement machines.

6. Global Supply Chain Resilience

- Diversification: PCB assembly manufacturers are diversifying their supply chains to reduce risks.

- Local Production: Trend towards more localized production to reduce shipping times and costs.

- Digital Supply Networks: Implementation of blockchain and other technologies for improved supply chain transparency and efficiency.

How Turnkey Solutions are Shaping the Future

Turnkey PCB assembly services are well-positioned to leverage these emerging trends:

- Integrated Innovation: Turnkey providers can more easily implement new technologies across the entire production process.

- Comprehensive Data Utilization: With control over the entire process, turnkey manufacturers can better utilize data for optimization and quality improvement.

- Agile Adaptation: Turnkey solutions allow for quicker adaptation to new materials, designs, and manufacturing techniques.

- Sustainable Practices: Integrated processes enable more effective implementation of sustainable and eco-friendly practices.

- Enhanced Customization: Turnkey providers can offer more customized solutions, leveraging advanced manufacturing techniques.

As these trends continue to evolve, companies that partner with forward-thinking turnkey PCB assembly manufacturers will be best positioned to take advantage of these advancements. The future of PCB manufacturing and assembly is one of increased efficiency, sustainability, and customization, all of which align perfectly with the turnkey model.

In conclusion, the PCB assembly industry is on the cusp of significant transformations. By choosing a turnkey PCB assembly service that is investing in these future technologies, companies can ensure they stay ahead of the curve, benefiting from the latest advancements in PCB manufacturing and assembly.

Conclusion and Next Steps

As we’ve explored throughout this article, turnkey PCB manufacturing and assembly offers a multitude of benefits for businesses of all sizes. From cost savings and improved quality control to faster time-to-market and simplified project management, the advantages of choosing a turnkey PCB assembly service are clear.

Key Takeaways:

- Integrated Efficiency: Turnkey solutions streamline the entire PCB production process, from design to final assembly.

- Cost-Effectiveness: While initial costs may seem higher, turnkey services often lead to significant long-term savings.

- Quality Assurance: Consistent standards and comprehensive testing throughout the process result in higher quality products.

- Time Savings: Faster turnaround times and reduced delays help you meet tight market deadlines.

- Scalability: Turnkey providers can easily adjust to your changing production needs, from prototypes to high-volume runs.

- Future-Ready: As the industry evolves, turnkey manufacturers are well-positioned to adopt new technologies and practices.

The global electronics market is more competitive than ever, and choosing the right PCB assembly manufacturer can make all the difference in your product’s success. Whether you’re a startup launching your first product or an established company looking to optimize your production process, turnkey PCB assembly services offer a compelling solution.

Ready to Optimize Your PCB Production?

At JHYPCB, we’re committed to providing top-tier turnkey PCB manufacturing and assembly services. Our state-of-the-art facilities in China combine cutting-edge technology with years of expertise to deliver high-quality PCBs at competitive prices.

We invite you to experience the benefits of turnkey PCB assembly for yourself:

- Get a Quote: Contact us today for a customized quote tailored to your specific project needs.

- Consult Our Experts: Our team is ready to answer your questions and provide guidance on optimizing your PCB design for manufacturing.

- Start Your Project: Whether you need prototype PCB assembly or high-volume production, we’re equipped to handle your requirements.

Don’t let PCB manufacturing challenges hold back your innovation. Partner with JHYPCB and take the first step towards streamlined, efficient, and high-quality PCB production.

Contact us now to discuss your PCB assembly needs and discover how our turnkey solutions can propel your project to success.

FAQs on Turnkey PCB Assembly

To help you better understand turnkey PCB assembly services, we’ve compiled a list of frequently asked questions:

Turnkey PCB assembly is a comprehensive service that handles all aspects of PCB production, from design review and component sourcing to PCB fabrication, assembly, and testing. It’s a “one-stop-shop” solution for getting your PCBs manufactured and assembled.

Traditional PCB manufacturing often involves working with multiple vendors for different stages of production. Turnkey assembly consolidates all these stages under one roof, streamlining the process and reducing potential communication issues and delays.

Key advantages include time and cost savings, improved quality control, simplified project management, and the ability to scale production more easily. Turnkey services also often provide valuable design for manufacturing (DFM) feedback.

While initial quotes for turnkey services might seem higher, they often result in overall cost savings due to increased efficiency, reduced errors, and economies of scale. It’s important to consider the total cost of ownership rather than just the upfront price.

Turnaround times can vary depending on the complexity of the project and production volume. However, turnkey services generally offer faster lead times compared to traditional methods, often reducing total production time by 30-50%.

Yes, most turnkey PCB assembly providers can accommodate a range of production volumes, from small prototype runs to high-volume production. This flexibility is one of the key advantages of turnkey services.

Turnkey assembly can handle a wide range of PCB types, including single-layer, multi-layer, rigid, flex, and rigid-flex PCBs. Advanced turnkey providers can also work with special materials and high-density interconnect (HDI) boards.

Turnkey providers typically implement comprehensive quality control measures throughout the production process. This often includes automated optical inspection (AOI), X-ray inspection, in-circuit testing (ICT), and functional testing.

While it’s best to finalize your design before starting production, many turnkey providers can accommodate changes, especially during the prototyping phase. However, changes during production may impact costs and lead times.

Look for a provider with a solid track record, good communication, advanced manufacturing capabilities, and strong quality control processes. Consider factors like their location, capacity, certifications, and ability to meet your specific project requirements.

We hope these FAQs have helped clarify some common questions about turnkey PCB assembly. If you have any further questions or specific requirements for your PCB project, don’t hesitate to reach out to our team at JHYPCB. We’re here to provide expert guidance and top-quality turnkey PCB assembly services tailored to your needs.

Related Posts

- Demystifying THT PCB Assembly: A Comprehensive Guide

- What is SMT Assembly? A Comprehensive Guide to Surface Mount Technology

- PCB Assembly Cost: A Comprehensive Guide for Cost-Effective PCB Manufacturing

- What is a PCB Manufacturer? The Definitive Guide

- Custom PCB Assembly Services for Low-Volume & Specialty Needs

- Custom PCB Fabrication in China – Prototyping & Mass Production

- Expedited PCB Services – Quick Turnaround for Your Urgent Needs

- Leveraging Turnkey PCB Assembly Manufacturing Services

- Choosing the Right PCB Assembly Manufacturer for Your Needs

- What Is Prototype PCB Assembly?

- How to Get a Quote and Order PCB Assembly?

- Electronic PCB Assembly Process and Flow Chart

- What is the defference between PCB and PCBA?

- The Main PCB Assembly Process Steps

- Top 10 Factors to Consider When Choosing a PCB Assembly Company