Table of Contents

Introduction: The Dominance of FR-4 in PCB Manufacturing

Printed circuit boards (PCBs) are the cornerstone of modern electronics, powering everything from smartphones to industrial automation systems. With the global PCB market projected to reach $89 billion by 2026, selecting the right material is critical for balancing performance, cost, and reliability. Among countless options, FR-4 reigns supreme, accounting for over 80% of standard PCB production worldwide. Why is FR-4 the preferred choice for engineers and manufacturers? Its flame-retardant epoxy and fiberglass composition delivers unmatched affordability, mechanical strength, and versatility, making it ideal for applications from consumer electronics to automotive systems. As demand for eco-friendly materials and high-performance PCBs grows in 2025, driven by 5G and IoT innovations, FR-4 continues to evolve with variants like halogen-free options. In this article, we dive into the unique properties, benefits, and applications of FR-4 PCBs, and why JHYPCB, a trusted leader in PCB manufacturing, leverages FR-4 to deliver tailored, high-quality solutions. Curious about what makes FR-4 stand out? Let’s explore.

What is FR-4 Material?

FR-4, short for Flame Retardant 4, is the cornerstone material of modern printed circuit board manufacturing. This fiberglass-reinforced epoxy laminate combines structural stability with exceptional electrical and thermal properties, making it the most widely used PCB substrate globally. But what exactly is FR-4, and why is it so prevalent?

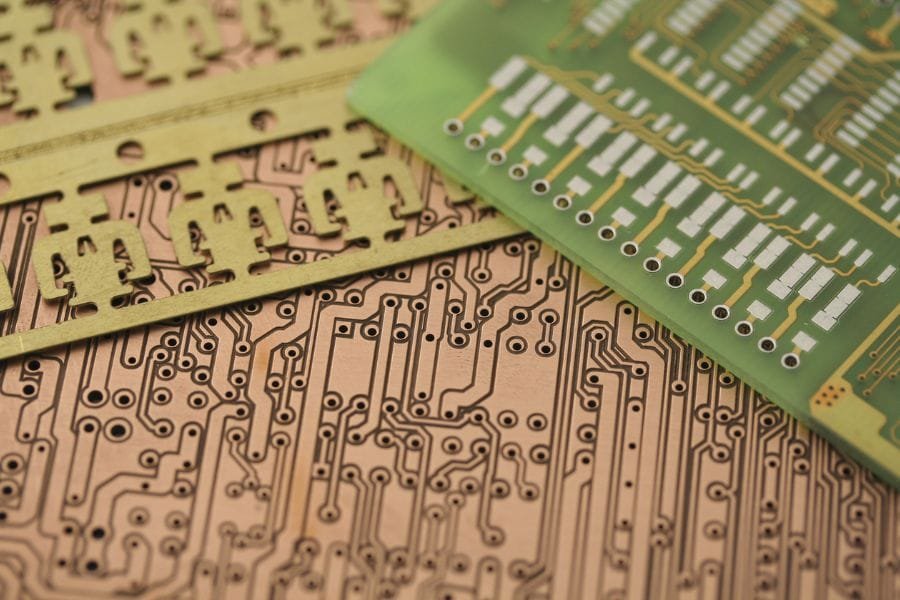

Composition and Structure

FR-4 consists of a woven fiberglass cloth impregnated with a flame-retardant epoxy resin. The fiberglass provides mechanical strength, typically with a tensile strength of 20,000–30,000 PSI, while the epoxy resin ensures durability and resistance to environmental factors. The material meets the UL94 V-0 standard, meaning it self-extinguishes in case of fire, ensuring safety in electronic applications. FR-4 sheets are typically light green to yellow, offering aesthetic flexibility for various designs.

Variants of FR-4

Not all FR-4 is created equal. The material comes in several grades to suit diverse needs:

- Standard FR-4: Ideal for general-purpose PCBs with a glass transition temperature (Tg) of 130–140°C.

- High-Tg FR-4: Offers enhanced thermal stability (Tg 170–180°C) for demanding applications like automotive electronics.

- Halogen-Free FR-4: Meets eco-friendly RoHS requirements, reducing environmental impact in consumer devices.

Historical Context

Introduced in the mid-20th century, FR-4 became the standard PCB material due to its cost-effectiveness and versatility. Its adoption surged with the rise of consumer electronics in the 1980s, and today, it powers everything from smartphones to industrial control systems. As the PCB industry evolves, FR-4 continues to adapt, with innovations like halogen-free variants aligning with 2025’s sustainability trends.

Why FR-4 Matters

FR-4’s balance of performance, affordability, and manufacturability makes it the go-to choice for engineers. Whether you’re designing a multilayer PCB or a compact IoT device, FR-4 delivers reliability. At JHYPCB, we specialize in crafting high-quality FR-4 PCBs tailored to your specifications, ensuring optimal performance for your projects. Want to learn how FR-4’s unique properties drive its dominance? Keep reading to explore its key characteristics.

Unique Characteristics of FR-4

The dominance of FR-4 in PCB manufacturing stems from its exceptional combination of properties, making it a versatile and reliable choice for countless applications. From mechanical strength to electrical insulation, FR-4’s unique characteristics set it apart from other PCB materials. Below, we explore the key properties that make FR-4 PCBs the industry standard, and why engineers trust them for everything from consumer electronics to marine systems.

- Mechanical Strength

FR-4’s woven fiberglass core provides remarkable mechanical durability, with a tensile strength of 20,000–30,000 PSI. This robustness ensures FR-4 can withstand physical stress, making it ideal for multilayer PCBs used in complex devices like laptops and automotive ECUs. Its high strength-to-weight ratio also keeps boards lightweight, enhancing portability in consumer products. - Electrical Properties

FR-4 boasts a dielectric constant (Dk) of approximately 4.5 at 1 MHz, ensuring excellent electrical insulation and signal integrity. Its low dielectric loss (Df ~0.02) minimizes signal degradation, making it suitable for standard-frequency applications like smartphones and industrial controls. These properties ensure reliable performance in diverse circuits. - Thermal Stability

With a glass transition temperature (Tg) of 130–180°C, FR-4 withstands the heat of reflow soldering, a critical process in PCB assembly. High-Tg variants (up to 180°C) offer enhanced stability for demanding environments, such as automotive electronics exposed to elevated temperatures. - Flame Resistance

FR-4 meets the UL94 V-0 standard, meaning it self-extinguishes within 10 seconds of flame exposure, ensuring safety in electronic devices. This flame-retardant property is critical for applications like medical equipment and household appliances, where fire safety is paramount. - Moisture Resistance

FR-4’s low water absorption rate (<0.15%) makes it highly resistant to humidity, ideal for marine and outdoor applications. Unlike other materials, FR-4 maintains its electrical and mechanical integrity in humid environments, ensuring long-term reliability. - Aesthetic Versatility

Available in colors ranging from light green to yellow, FR-4 offers aesthetic flexibility for branding or visual inspection. This versatility, combined with its performance, makes it a favorite for applications where appearance matters, such as consumer electronics.

FR-4 Performance Parameters

| Property | Value/Range | Benefit/Application |

|---|---|---|

| Tensile Strength | 20,000–30,000 PSI | Ensures durability in multilayer PCBs |

| Dielectric Constant (Dk) | ~4.5 at 1 MHz | Maintains signal integrity in standard circuits |

| Dielectric Loss (Df) | ~0.02 | Minimizes signal degradation |

| Glass Transition Temp (Tg) | 130–180°C | Supports reflow soldering, automotive use |

| Water Absorption | <0.15% | Ideal for marine and humid environments |

| Flame Resistance | UL94 V-0 | Ensures safety in consumer and medical devices |

Table: Key performance characteristics of FR-4, making it a versatile choice for PCB manufacturing.

Why do these characteristics make FR-4 so versatile? They enable it to perform reliably across diverse environments, from humid marine settings to high-stress industrial systems. At JHYPCB, we leverage FR-4’s unique properties to craft high-quality PCBs tailored to your needs. Curious about how these characteristics translate into real-world benefits? Read on to discover FR-4’s advantages.

Key Benefits of Using FR-4 for PCBs

The unique characteristics of FR-4 translate into tangible benefits that make it the preferred material for PCB manufacturing. From cost savings to versatility, FR-4 delivers unmatched value for engineers and manufacturers across industries. Whether you’re designing a compact IoT device or a robust automotive control system, FR-4’s advantages ensure performance without breaking the bank. Below, we explore the key benefits that solidify FR-4’s dominance in the PCB industry.

- Cost-Effectiveness

FR-4 is significantly more affordable than high-frequency materials like Rogers or PTFE, often costing 3–5 times less per square meter. This affordability makes it the go-to choice for mass-produced consumer electronics, such as smartphones and laptops, where cost control is critical. By choosing FR-4, manufacturers can reduce production expenses without compromising quality, enabling competitive pricing in the market. - Versatility

FR-4 supports a wide range of PCB configurations, from single-sided to multilayer boards with up to 20 layers or more. Its adaptability suits diverse applications, including wearables, industrial sensors, and automotive ECUs. Whether you need a simple single-layer board or a complex multilayer design, FR-4 delivers consistent performance across the board. - Processability

FR-4’s fiberglass-reinforced structure is easy to drill, cut, and laminate, streamlining the manufacturing process. This ease of processing reduces production time and costs, making it ideal for both prototyping and high-volume production. For instance, FR-4’s compatibility with automated drilling ensures precision in high-density PCB designs. - Reliability

With proven long-term stability, FR-4 PCBs maintain performance in demanding environments, from humid marine settings to high-vibration automotive systems. Its low moisture absorption (<0.15%) and mechanical strength (20,000–30,000 PSI) ensure durability, reducing the risk of board failure in critical applications like medical devices. - Compatibility with Surface Finishes

FR-4 is compatible with a variety of surface finishes, such as Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), and Organic Solderability Preservative (OSP). This flexibility allows manufacturers to tailor boards to specific requirements, such as corrosion resistance or enhanced solderability, ensuring optimal performance.

FR-4 vs. Other PCB Materials

Selecting the right material for your printed circuit board is crucial for meeting performance, cost, and application requirements. While FR-4 dominates as the go-to material for most PCBs, how does it stack up against alternatives like CEM-1, CEM-3, Rogers, and PTFE? This section compares FR-4 with these materials, highlighting its strengths, limitations, and ideal use cases. By understanding these differences, engineers can make informed decisions for their projects. Let’s dive into the comparison.

FR-4: The Industry Standard

FR-4, a fiberglass-reinforced epoxy laminate, offers a balanced combination of affordability, mechanical strength (20,000–30,000 PSI), and electrical performance (Dk ~4.5). With a glass transition temperature (Tg) of 130–180°C and UL94 V-0 flame resistance, it excels in standard applications like consumer electronics, automotive ECUs, and industrial controls. Its low cost—approximately 3–5 times less than high-frequency materials—makes it ideal for high-volume production.

Comparison with CEM-1 and CEM-3

- CEM-1: A cellulose-paper-based laminate with a single-layer fiberglass reinforcement, CEM-1 is cheaper than FR-4 (relative cost ~0.8). However, its lower Tg (100–120°C) and weaker mechanical strength limit it to simple, single-sided PCBs, such as those in basic household appliances. Unlike FR-4, CEM-1 struggles with multilayer designs and high-temperature soldering.

- CEM-3: Similar to FR-4 but with a non-woven fiberglass core, CEM-3 offers slightly better performance than CEM-1 at a comparable cost. Its Tg (120–130°C) and moderate electrical properties (Dk ~4.7) make it suitable for double-sided PCBs in low-cost electronics. However, FR-4 surpasses CEM-3 in durability and multilayer compatibility.

Comparison with High-Frequency Materials

- Rogers: Designed for high-frequency applications (e.g., RF and microwave circuits), Rogers materials have a lower dielectric constant (Dk ~3.0–3.5) and higher Tg (up to 280°C). They maintain stable impedance in 5G and aerospace applications but cost 3–5 times more than FR-4. For standard-frequency circuits, FR-4’s performance is sufficient at a fraction of the cost.

- PTFE: Polytetrafluoroethylene (Teflon-based) materials like PTFE offer exceptional electrical properties (Dk ~2.2) and thermal stability (Tg ~300°C), ideal for extreme environments like satellite systems. However, their high cost (5–7 times that of FR-4) and complex processing make them overkill for most consumer and industrial applications.

When to Choose FR-4

FR-4 shines in cost-sensitive, standard-frequency applications requiring durability and versatility. Its limitations—such as impedance instability in high-frequency circuits (>1 GHz) and lower thermal tolerance compared to Rogers—make it less suitable for specialized RF or aerospace designs. For these cases, JHYPCB offers guidance on alternative materials like high-Tg FR-4 or Rogers to meet specific needs.

Why FR-4 Stands Out

FR-4’s cost-effectiveness, ease of processing, and reliability make it the preferred choice for over 80% of PCBs worldwide. The table below summarizes the key differences, helping you decide when FR-4 is the right fit.

FR-4 vs Other PCB Materials: Cost & Performance Comparison

| Material | Relative Cost (per m²) | Dielectric Constant (Dk) | Tg (°C) | Mechanical Strength (PSI) | Key Applications |

|---|---|---|---|---|---|

| FR-4 | 1 | ~4.5 | 130–180 | 20,000–30,000 | Consumer electronics, automotive, industrial |

| CEM-1 | 0.8 | ~4.8 | 100–120 | 10,000–15,000 | Low-cost single-sided PCBs |

| CEM-3 | 0.9 | ~4.7 | 120–130 | 15,000–20,000 | Double-sided PCBs, low-cost electronics |

| Rogers | 3–5 | ~3.0–3.5 | 280 | 25,000–35,000 | RF/microwave, 5G, aerospace |

| PTFE | 5–7 | ~2.2 | 300 | 15,000–20,000 | Aerospace, high-frequency applications |

Table: FR-4 offers a cost-effective balance of performance, making it ideal for most PCB applications, while alternatives like Rogers and PTFE cater to specialized needs.

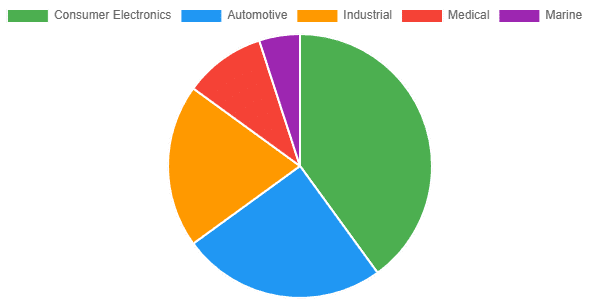

Applications of FR-4 PCBs

The versatility of FR-4 PCBs makes them a cornerstone of modern electronics, powering devices across diverse industries. From everyday gadgets to mission-critical systems, FR-4’s unique blend of affordability, durability, and performance ensures its widespread adoption. Why is FR-4 so ubiquitous? Its mechanical strength, electrical reliability, and environmental resilience make it ideal for a broad range of applications. Below, we explore how FR-4 drives innovation in key sectors, from consumer electronics to marine systems.

- Consumer Electronics

FR-4 PCBs are the backbone of consumer devices like smartphones, laptops, and TVs. Their cost-effectiveness allows manufacturers to produce high-volume products at competitive prices, while their mechanical strength (20,000–30,000 PSI) supports compact, multilayer designs. For example, FR-4’s dielectric constant (Dk ~4.5) ensures reliable signal transmission in high-density circuits, making it perfect for Wi-Fi routers and gaming consoles. - Automotive

In the automotive industry, FR-4 PCBs power engine control units (ECUs), infotainment systems, and advanced driver-assistance systems (ADAS). Their thermal stability (Tg 130–180°C) withstands the heat of under-hood environments, while their durability ensures performance in high-vibration settings. High-Tg FR-4 variants are increasingly used in electric vehicles (EVs) to meet rising thermal demands. - Industrial

FR-4 PCBs are widely used in industrial applications, including control panels, sensors, and automation equipment. Their low moisture absorption (<0.15%) and UL94 V-0 flame resistance ensure reliability in harsh environments, such as factories with high humidity or fire risks. For instance, FR-4 boards in PLCs (programmable logic controllers) maintain stable performance in industrial automation. - Medical

Medical devices, from diagnostic equipment to wearable health monitors, rely on FR-4 PCBs for their precision and safety. The material’s flame-retardant properties and electrical insulation (Dk ~4.5) ensure compliance with stringent medical standards. FR-4’s versatility supports compact designs in devices like glucose monitors, where reliability is critical. - Marine

FR-4’s exceptional moisture resistance makes it ideal for marine applications, such as navigation systems and communication equipment. Its low water absorption (<0.15%) prevents corrosion in humid, salty environments, ensuring long-term performance in marine electronics like GPS units and sonar systems. - Emerging Applications

As the electronics industry evolves in 2025, FR-4 continues to power emerging technologies like IoT devices and 5G infrastructure. Its affordability and compatibility with multilayer designs make it a top choice for compact IoT sensors, while halogen-free FR-4 variants align with growing environmental regulations. FR-4’s adaptability ensures it remains relevant in next-generation electronics.

FR-4 PCBs dominate in consumer electronics (40%), automotive (25%), industrial (20%), medical (10%), and marine (5%) applications, showcasing their versatility. Source: JHYPCB industry insights, 2025.

How FR-4 is Integrated into PCBs

The backbone of any PCB is its base material, and FR-4 serves as the foundation for most PCBs due to its durability and versatility. But how is FR-4 integrated into a PCB? The process involves precise lamination techniques, copper foil bonding, and tailored configurations to meet diverse design needs. From single-sided boards to complex multilayer designs, FR-4’s adaptability ensures it meets the demands of modern electronics. Below, we explore the key steps and configurations for integrating FR-4 into high-quality PCBs.

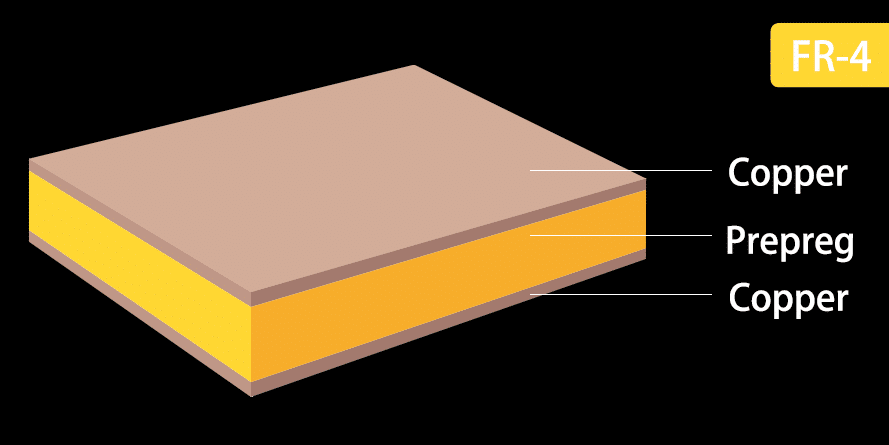

Lamination Process

FR-4 is integrated into PCBs through a lamination process that combines its fiberglass-reinforced epoxy core with copper foil. The process begins with prepreg (pre-impregnated fiberglass cloth with uncured epoxy resin), which is layered with copper foil and the FR-4 core. These layers are pressed together under high temperatures (typically 170–200°C) and pressure (300–500 PSI) to cure the epoxy, forming a solid, durable board. This process ensures strong adhesion and electrical insulation, with FR-4’s thermal stability (Tg 130–180°C) supporting reliable bonding during high-heat lamination.

Copper Foil Bonding

Copper foil, typically 0.035–0.070 mm thick, is bonded to one or both sides of the FR-4 core using heat and adhesives. This copper layer forms the conductive pathways for the PCB’s circuitry. For single-sided PCBs, copper is applied to one side, while double-sided and multilayer boards use copper on both sides. FR-4’s smooth surface and compatibility with adhesives ensure precise copper alignment, critical for high-density interconnect (HDI) designs in devices like smartphones.

PCB Configurations

FR-4’s versatility supports a range of PCB configurations:

- Single-Sided PCBs: A single copper layer on one side of the FR-4 core, ideal for simple electronics like power supplies or LED boards.

- Double-Sided PCBs: Copper on both sides, enabling more complex circuits for consumer devices like routers or audio equipment.

- Multilayer PCBs: Multiple FR-4 layers (up to 20 or more) interleaved with prepreg, perfect for advanced applications like servers or automotive ECUs.

- Flexible PCBs: Thin FR-4 variants (0.2–0.8 mm) support flex-rigid designs for wearables or medical devices.

Customization Options

FR-4 PCBs can be tailored to specific needs through thickness variations (0.2–3.2 mm) and surface finishes like HASL, ENIG, or OSP. Thin FR-4 boards suit compact designs, while thicker boards support high-power applications. FR-4’s ease of drilling and cutting allows for precise customization, enabling high-density layouts or unique board shapes. This flexibility makes FR-4 ideal for both prototyping and mass production.

How does FR-4 support such diverse PCB designs? Its robust mechanical properties and processability ensure reliability across configurations. At JHYPCB, we specialize in integrating FR-4 into custom PCBs with precision and efficiency, backed by ISO 9001-certified processes and rapid turnaround. Ready to choose the right FR-4 for your project? Continue reading to learn how to select the perfect material.

Choosing the Right FR-4 Material

Selecting the right FR-4 material for your PCB is crucial to ensuring performance, reliability, and cost-efficiency. With its versatility and range of variants, FR-4 supports diverse applications, from compact IoT devices to robust automotive systems. However, factors like thickness, flexibility, and environmental requirements can significantly impact your choice. How do you pick the perfect FR-4 for your project? Below, we outline key considerations to guide your selection process, ensuring your PCB meets design and performance goals.

Thickness Considerations

FR-4 is available in thicknesses ranging from 0.2 mm to 3.2 mm, measured in inch-based units (e.g., mils) or millimeters. The right thickness depends on your application:

- Thin FR-4 (0.2–0.8 mm): Ideal for space-constrained designs, such as USB connectors, Bluetooth modules, or wearable devices. Thin boards reduce weight and support high-density interconnect (HDI) layouts.

- Standard FR-4 (1.0–1.6 mm): The most common choice for general-purpose PCBs, balancing durability and versatility for consumer electronics like TVs or routers.

- Thick FR-4 (2.0–3.2 mm): Suited for high-power applications, such as industrial power supplies or automotive ECUs, where mechanical strength (20,000–30,000 PSI) is critical.

Flexibility Needs

For applications requiring flexibility, such as automotive dashboards or medical wearables, thin FR-4 (0.2–0.8 mm) can be used in flex-rigid or flexible PCBs. These boards withstand repeated bending without compromising electrical performance (Dk ~4.5). However, standard or thick FR-4 is preferred for rigid designs to ensure structural stability.

Avoiding Grooved Designs with Thin FR-4

Thin FR-4 boards are prone to fracturing in designs with grooves or cutouts, as their reduced thickness compromises mechanical integrity. For grooved PCBs, opt for thicker FR-4 (1.6 mm or above) to minimize the risk of damage during manufacturing or use, especially in high-stress environments like industrial controls.

Weight and Component Compatibility

The thickness of FR-4 directly affects the PCB’s weight and compatibility with components. Thin FR-4 reduces overall weight, making it ideal for lightweight electronics like drones or portable medical devices. However, ensure the thickness supports your components’ mounting requirements, as overly thin boards may not accommodate heavy connectors or high-power components.

Environmental and Regulatory Factors

Environmental conditions and regulations play a key role in FR-4 selection:

- High-Temperature Environments: Choose high-Tg FR-4 (Tg 170–180°C) for applications like automotive electronics, where standard FR-4 (Tg 130–140°C) may degrade under prolonged heat.

- RoHS Compliance: For eco-friendly designs, select halogen-free FR-4 to meet RoHS requirements, reducing environmental impact in consumer devices.

- Moisture Resistance: FR-4’s low water absorption (<0.15%) makes it suitable for humid environments, but verify the application’s exposure to ensure long-term reliability.

Choosing the right FR-4 involves balancing these factors with your project’s specific needs.

When to Avoid FR-4

While FR-4 PCBs are the go-to choice for most applications due to their affordability and versatility, they are not a one-size-fits-all solution. Certain conditions—such as extreme temperatures, lead-free soldering requirements, or high-frequency signals—can push FR-4 beyond its limits. When does FR-4 fall short, and what alternatives should you consider? Below, we outline key scenarios where FR-4 may not be the best choice and recommend solutions to meet your project’s needs.

High-Temperature Environments

Standard FR-4 has a glass transition temperature (Tg) of 130–140°C, with high-Tg variants reaching up to 180°C. However, in extreme environments like aerospace electronics or industrial furnaces, where temperatures exceed 180°C, FR-4 can soften or degrade, compromising reliability. Alternative: Consider materials like polyimide (Tg ~250–300°C) or high-Tg FR-4 for improved thermal stability in demanding applications.

Lead-Free Soldering Requirements

For RoHS-compliant PCBs, lead-free soldering is mandatory, often requiring reflow temperatures up to 250°C. Standard FR-4 may not withstand these peak temperatures, risking delamination or material breakdown. Alternative: High-Tg FR-4 (Tg 170–180°C) or halogen-free FR-4 can handle lead-free soldering, ensuring compliance and durability in consumer electronics.

High-Frequency Signals

FR-4’s dielectric constant (Dk ~4.5) and dielectric loss (Df ~0.02) make it suitable for standard-frequency circuits but inadequate for high-frequency applications (>1 GHz), such as RF or microwave circuits in 5G infrastructure. FR-4 struggles to maintain stable impedance, leading to signal loss or fluctuations. Alternative: Rogers materials (Dk ~3.0–3.5) or PTFE (Dk ~2.2) offer superior electrical performance for high-frequency designs.

When Alternatives Are Needed

While FR-4 excels in cost-sensitive, general-purpose applications, specialized projects may require alternatives:

- Polyimide: Ideal for high-temperature aerospace or military applications.

- Rogers: Preferred for RF/microwave circuits in 5G or radar systems.

- PTFE: Suited for extreme high-frequency or harsh-environment applications like satellites.

These materials come at a higher cost (3–7 times that of FR-4), but they deliver critical performance where FR-4 falls short.

Understanding when to avoid FR-4 is key to optimizing your PCB design.

Industry Trends and FR-4 in 2025

As the global PCB market is projected to reach $89 billion by 2026, the electronics industry in 2025 is driven by rapid advancements in 5G, IoT, electric vehicles (EVs), and sustainability initiatives. FR-4 PCBs, with their affordability and versatility, remain at the forefront of these trends, powering over 80% of standard PCBs worldwide. How does FR-4 adapt to the evolving demands of modern electronics? From high-performance variants to eco-friendly options, FR-4 continues to evolve, ensuring its relevance in cutting-edge applications. Below, we explore key industry trends and FR-4’s role in shaping the future.

5G and IoT Expansion

The rollout of 5G networks and the proliferation of IoT devices are driving demand for compact, reliable PCBs. FR-4’s compatibility with high-density interconnect (HDI) designs and multilayer configurations (up to 20 layers) makes it ideal for IoT sensors, smart home devices, and 5G base stations. Its dielectric constant (Dk ~4.5) supports standard-frequency circuits, while high-Tg FR-4 (Tg 170–180°C) ensures stability in 5G modules exposed to thermal stress.

Electric Vehicle Growth

The EV market, expected to grow at a 22% CAGR through 2030, relies on robust PCBs for battery management systems (BMS), inverters, and ECUs. FR-4’s mechanical strength (20,000–30,000 PSI) and thermal stability (Tg 130–180°C) make it a cost-effective choice for automotive applications, particularly in high-vibration environments. High-Tg FR-4 variants meet the increasing thermal demands of EV powertrains.

Sustainability and RoHS Compliance

With stricter environmental regulations, such as RoHS and REACH, halogen-free FR-4 is gaining traction in 2025. These eco-friendly variants reduce hazardous substances, aligning with sustainability goals in consumer electronics and medical devices. FR-4’s low water absorption (<0.15%) further enhances its reliability in humid environments, supporting green designs without sacrificing performance.

Miniaturization and Advanced Manufacturing

The push for smaller, more powerful devices drives demand for thinner FR-4 boards (0.2–0.8 mm) and advanced manufacturing techniques like laser drilling. FR-4’s ease of processing supports high-precision HDI PCBs, enabling compact designs for wearables and medical implants. Its compatibility with surface finishes like ENIG ensures reliable soldering for fine-pitch components.

FR-4’s adaptability ensures it remains a cornerstone of PCB manufacturing in 2025, meeting the demands of emerging technologies while maintaining cost efficiency.

FAQ: Common Questions About FR-4 PCBs

To help you better understand FR-4 PCBs, we’ve compiled answers to the most common questions about this versatile material. Whether you’re an engineer or a procurement specialist, these insights will guide your PCB decisions. Have more questions? Contact JHYPCB at sales@pcbjhy.com for expert support.

What is an FR-4 PCB?

An FR-4 PCB is a printed circuit board made from a fiberglass-reinforced epoxy laminate, known for its affordability and durability. With a dielectric constant (Dk ~4.5) and mechanical strength (20,000–30,000 PSI), FR-4 is the industry standard for consumer electronics, automotive, and industrial applications.

Why is FR-4 so popular for PCBs?

FR-4’s popularity stems from its cost-effectiveness (3–5 times cheaper than Rogers), versatility (supports single to multilayer designs), and reliability (low moisture absorption <0.15%). It powers over 80% of PCBs globally, ideal for smartphones, ECUs, and IoT devices.

Is FR-4 suitable for high-frequency applications?

FR-4 is less effective for high-frequency signals (>1 GHz) due to its dielectric constant (Dk ~4.5), which can cause signal loss. For RF or 5G applications, consider Rogers (Dk ~3.0–3.5) or PTFE (Dk ~2.2). JHYPCB can recommend the right material.

Can FR-4 withstand high temperatures?

Standard FR-4 (Tg 130–140°C) suits most applications, but high-Tg FR-4 (Tg 170–180°C) is better for high-temperature environments like automotive electronics. For extreme heat (>180°C), polyimide is a better choice. Consult JHYPCB for tailored solutions.

How do I choose the right FR-4 thickness?

FR-4 thickness (0.2–3.2 mm) depends on your project. Thin boards (0.2–0.8 mm) suit compact IoT devices, while thicker boards (1.6–3.2 mm) support high-power industrial PCBs. JHYPCB offers guidance to match thickness to your needs.

Are there eco-friendly FR-4 options?

Yes, halogen-free FR-4 meets RoHS and REACH standards, reducing environmental impact. These variants are popular in consumer electronics and medical devices, offering the same reliability (Tg 130–180°C) with greener credentials.

How can JHYPCB help with FR-4 PCBs?

JHYPCB specializes in high-quality, customized FR-4 PCBs, from prototyping to mass production. With ISO 9001-certified processes, we ensure precision and fast delivery. Contact us at sales@pcbjhy.com to discuss your project today.

Why Choose JHYPCB for FR-4 PCBs?

When selecting a partner for FR-4 PCBs, JHYPCB stands out as a trusted leader in 2025. Why choose us? Our ISO 9001-certified manufacturing delivers high-quality FR-4 PCBs, from single-sided to multilayer designs, tailored for 5G, IoT, and EV applications. With over a decade of expertise, we offer rapid prototyping, precision lamination (0.2–3.2 mm thickness), and halogen-free options to meet RoHS standards. Our 24/7 technical support ensures seamless project execution, while competitive pricing keeps your costs low. Whether you need HDI PCBs for wearables or robust boards for automotive ECUs, JHYPCB guarantees reliability and fast delivery. Ready to elevate your project? Contact us for custom FR-4 solutions today.

Conclusion: Why FR-4 Remains the Industry Standard

FR-4 PCBs continue to dominate the electronics industry in 2025, powering over 80% of standard PCBs worldwide. Why does FR-4 remain the go-to choice? Its unmatched combination of cost-effectiveness, versatility, and reliability—boasting mechanical strength (20,000–30,000 PSI), low moisture absorption (<0.15%), and thermal stability (Tg 130–180°C)—makes it ideal for applications from smartphones to automotive ECUs. With variants like high-Tg and halogen-free FR-4, it adapts to emerging trends like 5G, IoT, and sustainability, ensuring relevance in a $89 billion PCB market. While alternatives like Rogers or PTFE serve specialized needs, FR-4’s affordability and processability keep it unrivaled for most projects.

Advanced Learning:

- Unveil the mystery of high TG PCB circuit boards Materials

- Why is FR4 Used to Make High Tg PCBs?

- Custom Circuit Board Printing

- PCB Manufacturer In China

- Fast Turn Prototype PCB Service

- Fast Prototype PCB Assembly Service

- Why Choose Chinese PCB Manufacturer

- What Is FR-4 Material In PCB Fabrication?

- Complete Introduction of Flexible Circuit Board Materials